How to Optimize Your Production Efficiency with the Right PVC Door Cutting Machine Strategies

In today's fast-paced manufacturing environment, optimizing production efficiency is crucial for maintaining competitiveness, especially in the PVC door industry. A report from the Freedonia Group projects that the demand for PVC doors will increase by 4.5% annually, driven by rising construction activities and renovations. To meet this growing demand, manufacturers must adopt advanced methodologies and machinery, particularly focusing on the use of a PVC Door Cutting Machine. Implementing innovative cutting strategies not only streamlines production processes but also reduces waste and enhances precision. As businesses seek to maximize throughput while minimizing costs, investing in the right cutting technology becomes essential. This blog will explore effective strategies to optimize production efficiency using the latest advancements in PVC Door Cutting Machines, ensuring companies can meet market demands while improving their bottom line.

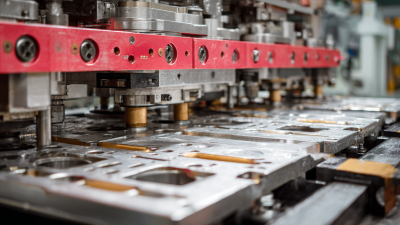

Identifying the Key Features of an Efficient PVC Door Cutting Machine

When optimizing your production efficiency with a PVC door cutting machine, understanding the key features of an efficient model can significantly enhance operations. A robust PVC door cutting machine should incorporate precision cutting technology, ensuring that each cut is accurate and minimizes waste. Features like automated adjustments and programmable settings allow for quick customization based on specific project needs, which streamlines the production process.

Moreover, advanced machines are increasingly integrating smart technologies that share similarities with advancements in AI, such as emotion recognition. Just as recent developments enable AI to interpret human expressions, modern PVC door cutting machines can analyze operational metrics in real time, making intelligent decisions to optimize performance. These enhancements can lead to increased production speed and reduced error rates, ultimately improving overall efficiency in PVC door manufacturing.

Evaluating Your Production Needs for Optimal Machine Selection

When evaluating your production needs for optimal PVC door cutting machine selection, it is crucial to analyze various factors influencing efficiency. Just like in the realm of automotive manufacturing where the integration of machine learning frameworks has overcome traditional limitations in process monitoring, similar strategies can be applied in the selection of machines for the PVC industry. By utilizing data-driven assessments, manufacturers can pinpoint specific requirements—such as material types, production volume, and precision levels—leading to more informed and effective machine choices.

Incorporating advanced analytical methods, such as the analytic hierarchy process, can significantly streamline decision-making. This approach allows you to weigh different variables, enabling a sustainable and economically viable selection process. By aligning machine capabilities with production objectives, businesses can enhance their operational efficiencies and drive production output. Thus, leveraging strategic evaluation methods not only improves the machine selection process but also contributes to a more optimized and streamlined production environment.

Production Efficiency Optimization with PVC Door Cutting Machines

Implementing Effective Maintenance Strategies for Longevity

Implementing effective maintenance strategies for your PVC door cutting machines is crucial for maximizing production efficiency and ensuring the longevity of your equipment.

According to a report by the National Institute of Standards and Technology (NIST), poorly maintained machinery can lead to an increase in downtime by as much as 20%. Regular maintenance not only extends the lifespan of your cutting machines but also optimizes their performance, resulting in better production outputs and reduced operational costs.

One key strategy is the establishment of a scheduled maintenance routine, which should include inspections and replacements of wear parts. The Machinery Maintenance report highlights that companies practicing proactive maintenance can reduce unexpected breakdowns by 30%. By investing in quality maintenance, you can ensure that the precision of cuts remains consistent, which is fundamental in the production of high-quality PVC doors. Additionally, providing training for employees on the proper use and basic maintenance of machines can further enhance efficiency and reduce the risk of errors, creating a more streamlined production process overall.

Training Your Team on Best Practices for Machine Operation

Training your team on best practices for operating a PVC door cutting machine is crucial for optimizing production efficiency and enhancing workplace safety. Proper training not only improves the proficiency of your workforce but also minimizes the risks associated with machine operation. Employees should be educated on the specific hazards related to cutting machinery and equipped with the skills necessary to identify and manage those risks effectively.

Regular safety drills and hands-on workshops can reinforce these training sessions, ensuring that team members are both confident and competent in their roles.

Training your team on best practices for operating a PVC door cutting machine is crucial for optimizing production efficiency and enhancing workplace safety. Proper training not only improves the proficiency of your workforce but also minimizes the risks associated with machine operation. Employees should be educated on the specific hazards related to cutting machinery and equipped with the skills necessary to identify and manage those risks effectively.

Regular safety drills and hands-on workshops can reinforce these training sessions, ensuring that team members are both confident and competent in their roles.

Moreover, fostering a culture of safety awareness within your team is essential. Establishing guidelines that emphasize safety protocols and encouraging open communication about potential hazards can help create an environment where employees are proactive in protecting themselves and their colleagues. This approach not only leads to a safer workplace but also enhances operational efficiency, as a well-trained team can respond quickly and effectively to any equipment-related issues that arise during production.

Investing in comprehensive training and development initiatives is an essential step towards achieving a balanced focus on productivity and safety in your manufacturing environment.

Exploring Advanced Cutting Techniques to Enhance Output Quality

In the quest for optimizing production efficiency, advanced cutting techniques for PVC doors have emerged as critical drivers of output quality. Recent reports indicate that automation and artificial intelligence (AI) are reshaping the landscape of manufacturing, enabling operations managers to streamline processes and reduce costs significantly. For instance, studies have shown that AI can enhance productivity by up to 40%, utilizing data analytics to predict machine performance and reduce downtime.

The garment and manufacturing industries serve as prime examples of this transformation. Automation technologies, particularly in cutting garments, have led to a 20-30% increase in production speed without compromising quality. By adopting advanced cutting machines equipped with precision software, manufacturers can achieve cleaner cuts and minimize material waste, ultimately translating to higher profit margins. Moreover, the integration of generative AI tools enables operators to simulate different cutting strategies, optimizing each production run for efficiency and quality.

As manufacturers look to the future, embracing these advanced techniques will not only improve operational efficiency but also ensure that they remain competitive in an increasingly automated marketplace. With the right strategies, the potential for enhanced output quality is immense, positioning businesses to thrive in a rapidly evolving industrial environment.

How to Optimize Your Production Efficiency with the Right PVC Door Cutting Machine Strategies

| Cutting Technique | Efficiency Improvement (%) | Cost Reduction ($) | Output Quality Rating (1-10) |

|---|---|---|---|

| Laser Cutting | 25 | 300 | 9 |

| CNC Cutting | 30 | 400 | 8 |

| Water Jet Cutting | 20 | 250 | 7 |

| Oscillating Blade Cutting | 15 | 200 | 6 |

| Plasma Cutting | 18 | 280 | 7 |

Related Posts

-

Global Excellence in Manufacturing with Chinese Quality for Best Pvc Door Cutting Machines

-

Unlocking the Advantages of State-of-the-Art Window Fabrication Equipment for Global Buyers

-

An In-Depth Comparison of the Top Aluminium Manufacturing Machines for Efficient Production

-

Crafting Excellence: Trustworthy Wood Window Production Solutions from China to the World

-

7 Compelling Reasons to Choose the Best PVC Machinery for Your Business Success

-

Essential Factors to Consider When Evaluating Pvc Machinery for Your Production Needs