Global Buyers Discover High-Quality Chinese Aluminum Window Machinery: A New Era of Manufacturing Excellence

In recent years, the demand for high-quality Aluminum Window Machinery has surged globally, signaling a pivotal shift towards enhanced manufacturing standards and practices. As global buyers increasingly seek advanced machinery that offers both efficiency and precision, Chinese manufacturers have stepped up, showcasing their commitment to innovation and excellence in this competitive market. This blog explores how the landscape of Aluminum Window Machinery production is evolving, highlighting the advanced technologies and rigorous industry standards that are shaping the future of manufacturing. With a focus on quality and performance, Chinese manufacturers are not just meeting but exceeding international expectations, paving the way for a new era of manufacturing excellence that can cater to diverse market needs. Join us as we delve into the latest trends, innovations, and the promising future of Aluminum Window Machinery in the global market.

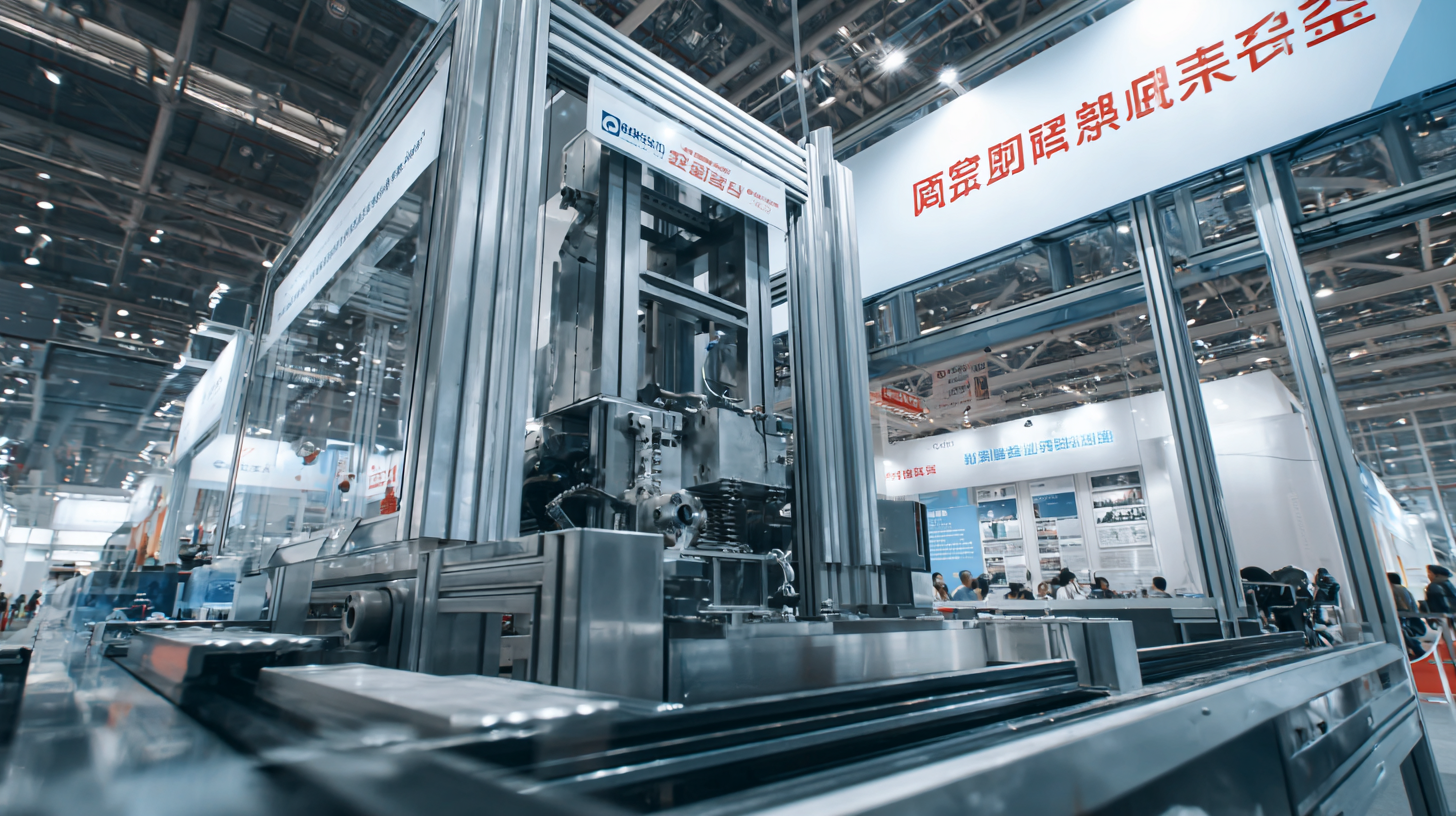

Emerging Trends in Chinese Aluminum Window Machinery for 2025: A Comprehensive Overview

As global demand for energy-efficient buildings rises, the aluminum window machinery sector in China is poised for significant evolution by 2025. Key trends emerging in this market highlight the integration of advanced automation and smart manufacturing techniques. These innovations not only enhance production efficiency but also ensure superior quality in the finished products. Manufacturers are increasingly adopting robotics and IoT technologies, allowing for a more streamlined workflow, reduced waste, and improved precision in window frame fabrication.

In addition to technological advancements, sustainability is becoming a core focus for Chinese aluminum window machinery. The shift towards eco-friendly materials and processes is evident, as companies explore ways to minimize their carbon footprint while delivering high-performance products. This green revolution is expected to resonate with an international audience, driving global buyers towards Chinese manufacturers who prioritize both quality and environmental responsibility. As such, the landscape of aluminum window production is transforming, setting new standards for excellence that are anticipated to dominate the industry within the next few years.

Global Buyers Discover High-Quality Chinese Aluminum Window Machinery: A New Era of Manufacturing Excellence

| Dimension | Value |

|---|---|

| Production Capacity (Units/Month) | 5000 |

| Average Machine Price (USD) | 15000 |

| Export Growth Rate (2023 vs 2022) | 15% |

| Market Share in Asia (%) | 35% |

| Sustainability Certification (%) | 80% |

| Innovation Rate (%) | 25% |

| Consumer Satisfaction Rate (%) | 92% |

The Impact of Automation and Robotics on Aluminum Window Manufacturing Efficiency

The aluminum window manufacturing industry is experiencing a remarkable transformation driven by automation and robotics. These advanced technologies are enhancing production efficiency and quality, allowing manufacturers to meet rising global demand while reducing costs. Automated systems streamline the production line, ensuring precision and consistency in every window frame, which is crucial for maintaining competitive advantage in the global marketplace.

Tips for Enhancing Automation in Manufacturing:

- Invest in training for your workforce to operate and maintain robotic systems effectively. A knowledgeable team is essential for optimal productivity.

- Regularly evaluate your production processes to identify areas where automation can yield significant improvements. Small adjustments can lead to substantial efficiency gains.

As manufacturers integrate more automated solutions, they can expect to see not only increased output but also a reduction in waste and downtime. Robotics can handle repetitive tasks with ease, which frees up human workers to focus on more complex and creative aspects of the manufacturing process. This synergy between human intelligence and machine efficiency heralds a new era of excellence in aluminum window production.

Sustainability in Manufacturing: Innovations in Eco-Friendly Aluminum Window Solutions

In the ever-evolving landscape of manufacturing, sustainability has emerged as a critical focus, especially in the production of aluminum window solutions. Innovations in eco-friendly practices are leading the way for global buyers seeking high-quality machinery that not only enhances efficiency but also minimizes environmental impact. From utilizing recycled materials to energy-efficient manufacturing processes, the aluminum window industry is committed to reducing its carbon footprint and promoting a circular economy.

Recent advancements in technology have paved the way for machinery that supports these sustainable practices. Manufacturers are increasingly investing in equipment that integrates smart technologies, allowing them to optimize resource use and reduce waste. For instance, cutting-edge aluminum window machinery now features automated systems that streamline production while ensuring precision and quality. These innovations not only enhance productivity but also align with global sustainability goals, making it an ideal choice for eco-conscious buyers.

As more businesses prioritize sustainability, the demand for high-quality, eco-friendly aluminum window solutions is set to rise. This shift presents a significant opportunity for manufacturers to showcase their commitment to the environment while delivering exceptional products. By embracing modern technologies and sustainable practices, the aluminum industry is not only enhancing manufacturing excellence but also contributing to a more sustainable future.

Key Market Insights: Global Demand for High-Quality Aluminum Window Machinery

The global market for high-quality aluminum window machinery is witnessing significant growth as buyers increasingly recognize the advantages of superior manufacturing solutions. As outlined in recent analysis, the Aluminum Windows and Doors market is projected to reach a staggering valuation of USD 66,963.6 million by 2023, driven by rising demand for energy-efficient and aesthetically pleasing building materials. This boom in demand reflects a broader trend towards modernization and sustainability in construction practices worldwide.

Moreover, the market for aluminum window machinery is set to benefit from ongoing advancements in technology that enhance production efficiency and product quality. With a compound annual growth rate (CAGR) expected to rise steadily, manufacturers are keenly focusing on innovation to meet the evolving needs of global buyers. As the construction industry progressively shifts towards high-quality materials, the importance of investing in state-of-the-art aluminum machinery cannot be overstated. This transition marks the beginning of a new era in manufacturing, where exceptional quality and performance are paramount.

Technological Advancements: Exploring Smart Manufacturing in the Aluminum Industry

In recent years, the aluminum industry has witnessed a significant transformation driven by technological advancements, particularly in smart manufacturing. According to a report by Smithers Pira, the global aluminum market is expected to grow at a CAGR of 5.4% from 2021 to 2026, highlighting the rising demand for innovative manufacturing solutions. Technologies such as Artificial Intelligence (AI), Internet of Things (IoT), and robotics are paving the way for enhanced efficiency and production precision in aluminum window machinery, enabling manufacturers to meet the growing consumer demand for sustainability and quality.

**Tip:** To stay competitive, businesses should invest in smart manufacturing technologies that automate processes and integrate real-time data analytics. This not only streamlines production but also enhances the overall quality of the end product.

Moreover, the integration of AI-driven monitoring systems allows manufacturers to reduce waste and energy consumption, essential factors in today’s environmentally conscious market. According to McKinsey, companies that adopt advanced technologies could improve their productivity by up to 30%. This shift to smart manufacturing is not just about cost-saving; it reflects a new standard of excellence that global buyers are actively seeking in high-quality Chinese aluminum window machinery.

**Tip:** Embrace emerging trends by attending industry trade shows and workshops, which can provide valuable insights into the latest innovations and best practices in aluminum manufacturing.

Technological Advancements in Chinese Aluminum Window Machinery

This chart illustrates the increasing global demand for high-quality Chinese aluminum window machinery from 2020 to 2023, highlighting the technological advancements and the shift towards smart manufacturing in the aluminum industry.